Steam Pyrolyst

Low cost Green Hydrogen or Methane

Hydrogen faces significant challenges in its production. From fossil fuels its production emits vast amounts of GHG. From green electricity costs are uneconomical. Steam Pyrolyst produces hydrogen below 2€/kg or methane below 0.50€/Nm3.

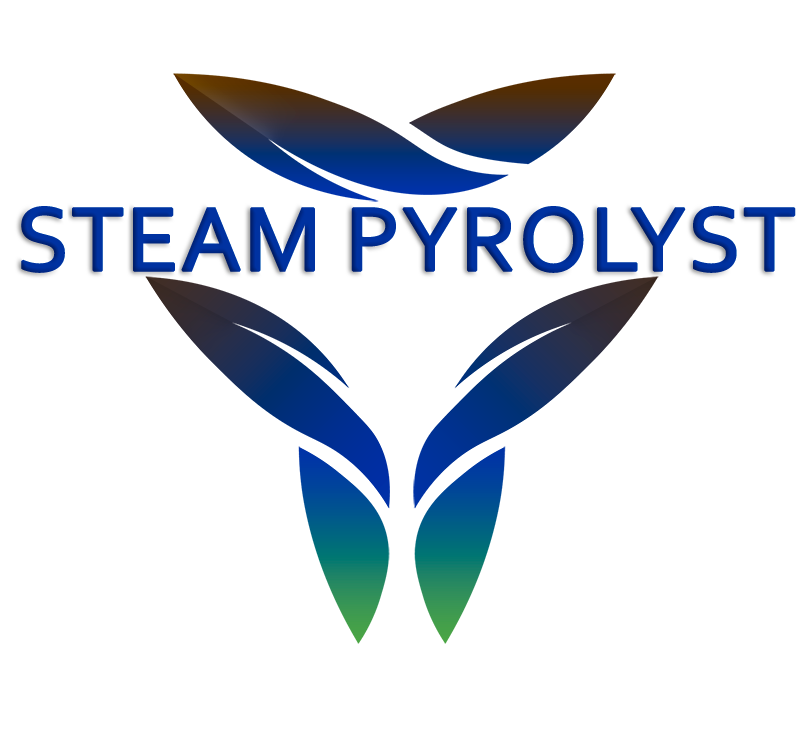

Steam Pyrolyst uses pyrolysis as pre-treatment at 200°C and then 600°C steam gasification to convert organic and plastic waste into green methane and charcoal. These products can then be converted into hydrogen.

Compared to conventional biogas and hydrogen production methods—such as wet fermentation, gasification, and water electrolysis—this process offers several operational and efficiency advantages, in terms of speed, feedstock flexibility, energy efficiency, and reduced emissions. For waste-rich regions and sustainability-driven operations, Steam Pyrolyst offers unbeatable low gas production costs.

Advantages of Steam Pyrolyst

Quality Control for Methane: Methane produced meets grid specs for combustion, calorific value, and purity (low H₂S, NH₃, CO). This is controlled by the most accurate sensors on the market, reducing down-time and worker involvement.

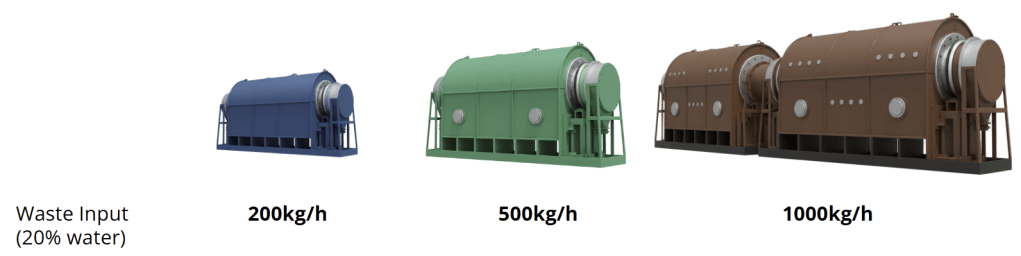

Fast Processing: Can convert waste to gas in about 20 minutes, compared to over ~30 days for classic wet fermentation. Different sizes are available as shown below.

Location independence: The location can be anywhere suitable waste streams are available. There is no need for green electricity, like is the case with Water Electrolysis.

Versatility: Suitable for nearly all organic materials and plastics, whereas wet fermentation struggles with low-moisture, fibrous and polymer feedstocks.

Energy Efficient: Uses ~20% of generated methane internally to produce steam, reducing outside energy dependence.

Carbon Utilization: Produces biochar, which can be used for fertilizer or further gasification to make hydrogen, instead of ash produced by boilers.

Compact and Scalable: The plant design is modular and can be deployed for small, local facilities or scaled for larger applications.

Low Emissions: The sealed vessel and lack of combustion limit harmful gas emissions (NOₓ, SOₓ), particularly beneficial compared to incineration or gasification methods.