Plastalyst

Breakthrough plastic

decomposition for

the circular economy

According to the UN, only 9% of 8.3 billion tons of plastic wastes have been recycled over the past 65 years. This is due to the low efficiency of catalysts in recycling and high costs of recycling facilities. Currently, plastic waste elimination requires high-heat incineration only available to large-scale recyclers.

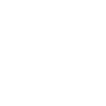

Our award-winning chemical catalyst Plastalyst turns this around, decomposing polymers to monomers. Uniquely, it works below 200°C and completely solvent-free.

This means we can recycle the unrecyclable: break down the most difficult-to-decompose plastics rather than sending them to incinerators or landfills. It is our vision to create a world, where all plastics are recycled.

What is Plastalyst?

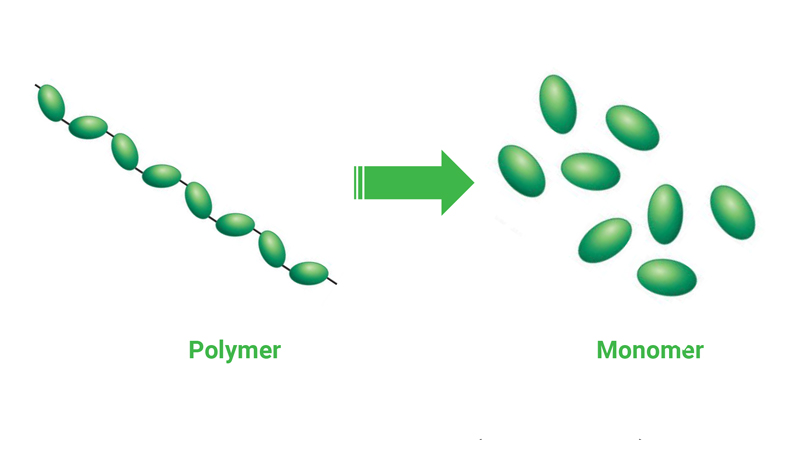

Plastalyst can be considered chemolysis and more specifically hydrolysis. This combines the affordability of mechanical recycling with the ability to recycles almost any plastics of pyrolysis. Making plastic recycling affordable has the power to keep plastics away from our oceans and environment, because integrating them into a circular economy becomes accessible and profitable.

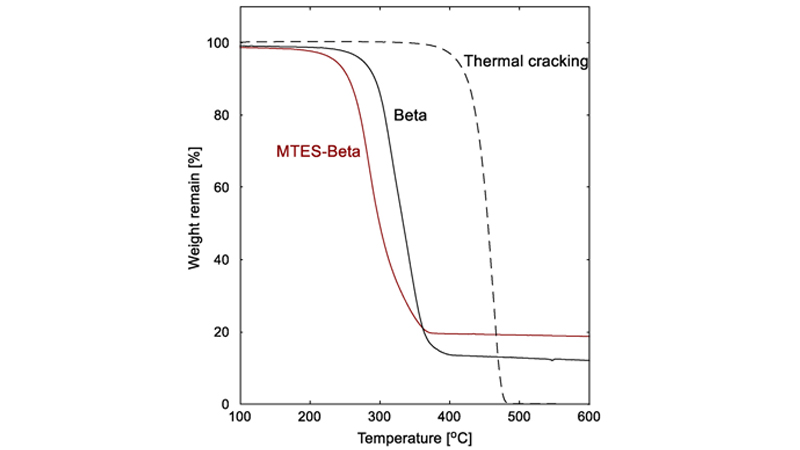

AC Biode is pioneering the recycling of several plastics. In the future all plastics will be recycled, even those that are multi-layered or deteriorated. Our first patent was granted on PE recycling and can be viewed here. Our catalyst decomposes PE at a lower temperature than other commonly applied methods into propylene.

Other Applications

Plastalyst recycles the most difficult to recycle plastics into monomers at low temperatures, to make new plastics. The reaction occurred at a temperature of only 200°C. Compared to other methods, our method has significant advantages such as low energy use, which results in lower operational cost.

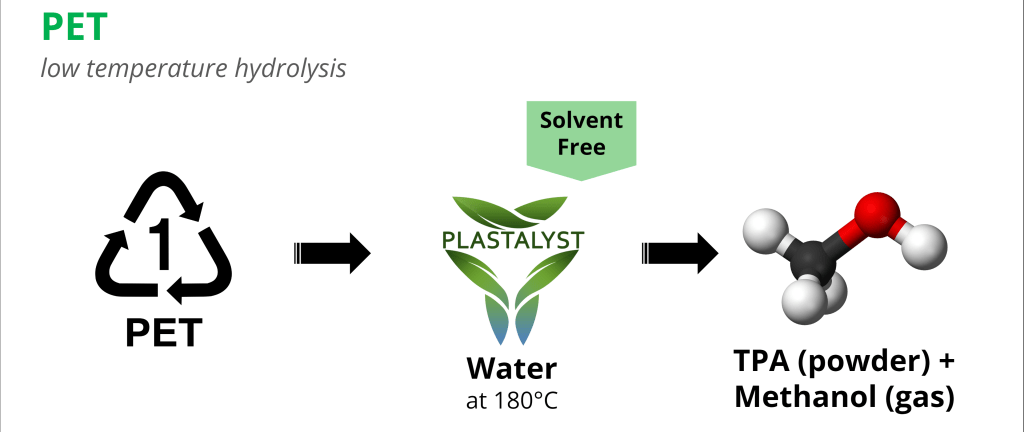

We are the first to recycle PET into TPA and methanol. This year we are testing at 1.2t scale for PET, PVC, PE, PP and mixed plastics.

Compared to other technologies, Plastalyst only requires 200°C and water as a solvent. Crucially, the catalysts are not using precious or rare-earth metals.

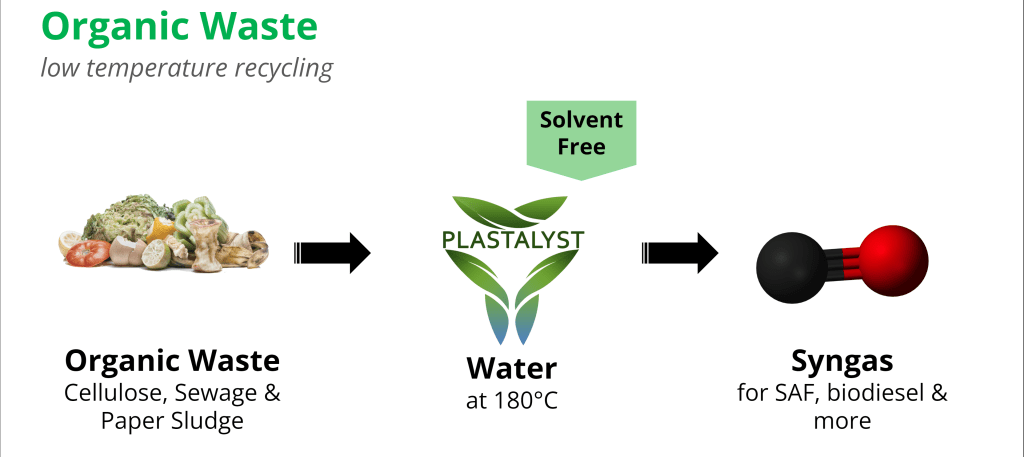

Plastalyst produces H2 and CO from organic waste. It uses only water, biomass and a reusable catalyst as input. Next, we use water in the reaction, less drying of biomass is needed, therefore it will cut the cost of preparing the material. Lastly, no solvent is needed and no CO2 is emitted in the reaction. Unlike organic methods, such as bio-digestion that require a lot of time, Plastalyst is a chemical method. The reaction occurs at below 200°C, takes only 2h and is highly scalable.

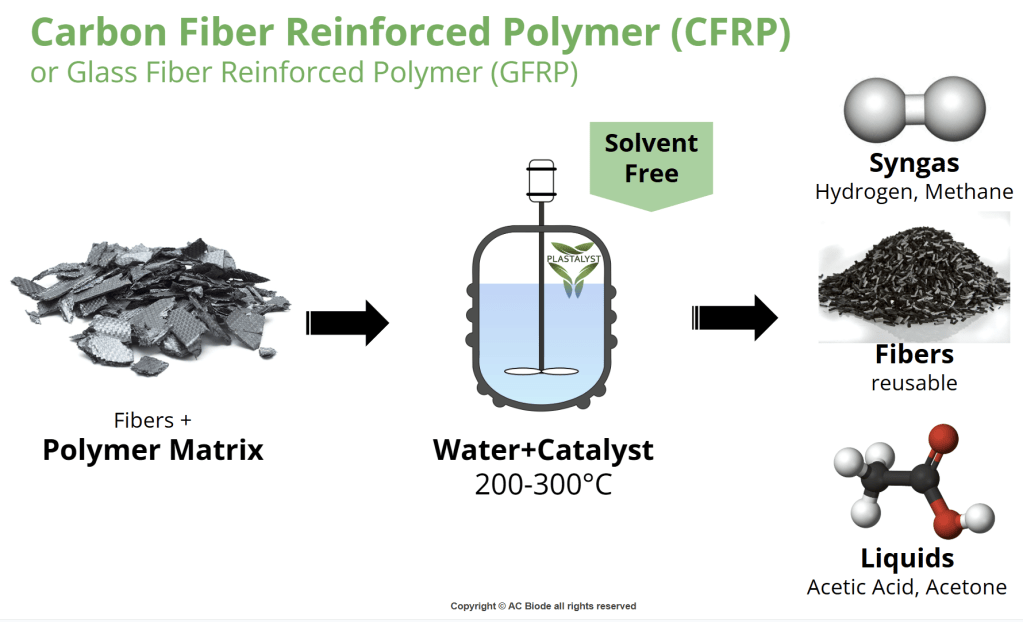

Recent pilots with large manufacturers have led to new methods in recycling composite materials, electronics and textiles. Please get in touch via the form below if you are interested in learning more.